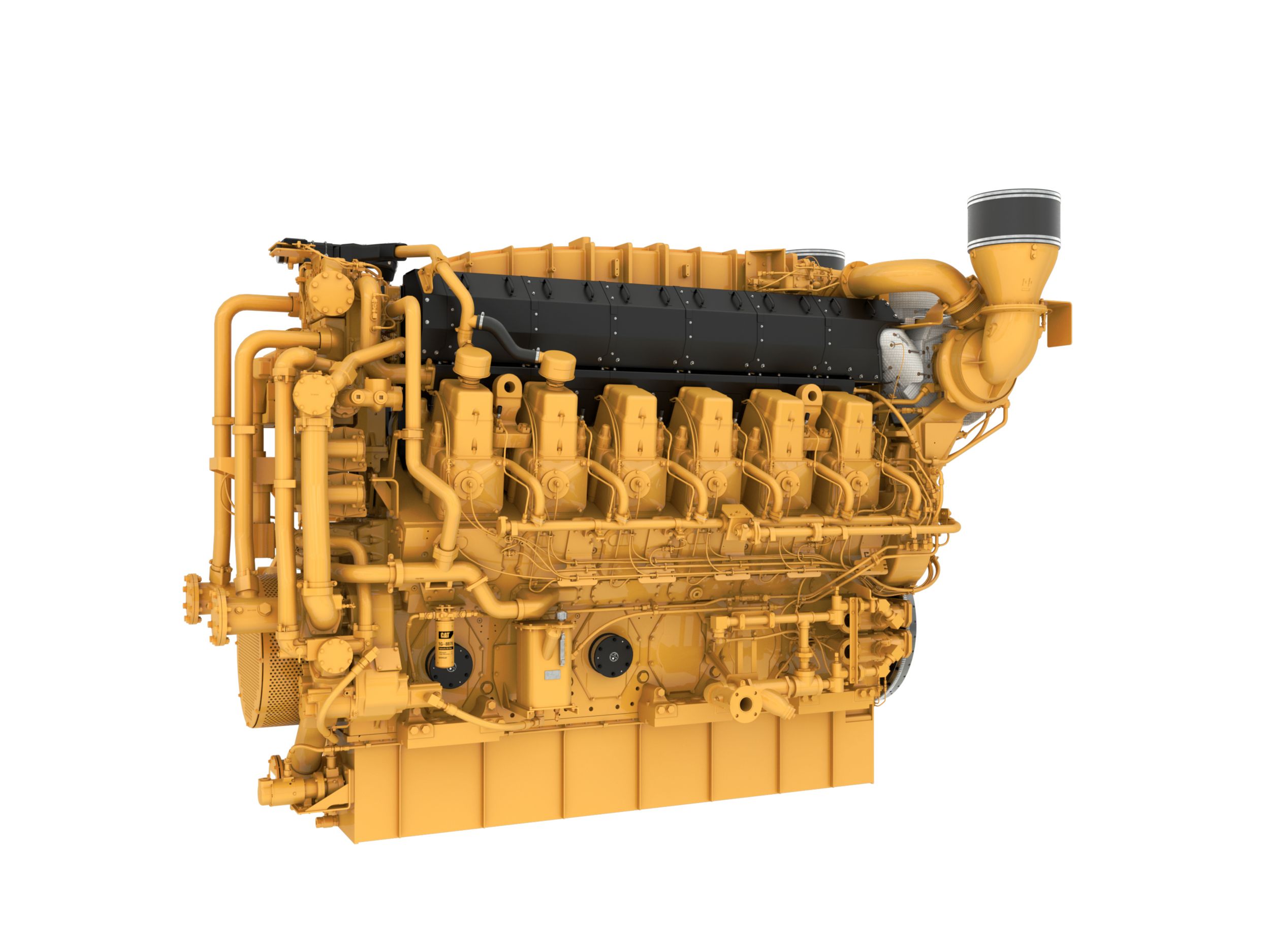

G3612 A4 Gas Compression Engine

Gas Compression Engines

-

Specification Summary

- Maximum Rating 3076 bkW

- Emissions NSPS Site Compliant Capable

- Displacement 254 l

- Minimum Rating 2796 bkW

- Download Brochure

Engine Specifications

| Maximum Rating | 3076 bkW |

| Emissions | NSPS Site Compliant Capable |

| Displacement | 254 l |

| Minimum Rating | 2796 bkW |

| Compression Ratio | Gen 1 (9.2:1) Gen 2 (7:6:1) |

| Aspiration | Turbocharged-Aftercooled |

| Rotation from Flywheel End | Counterclockwise |

| Flywheel Teeth | 255 |

| Weight - Dry | 26535 kg |

| Oil Change Interval | 5000 hours |

| Ignition, Protection | ADEM™4 |

| Stroke | 300 mm |

| Bore | 300 mm |

Capacity for Liquids

| Cooling System | 734 l |

| Lube Oil System - Refill | 1030 l |

Air Inlet System

Air cleaner — standard duty Inlet air adapter

Control System

A4 control system — provides electronic governing integrated with air/fuel ratio control and individual cylinder ignition timing control

Cooling System

Jacket water pump

Jacket water thermostats and housing

Aftercooler pump

Aftercooler water thermostats and housing

Two-stage aftercooler

Exhaust System

Dry wrapped exhaust manifolds

Vertical outlet adapter

Dry wrapped exhaust manifolds

Vertical outlet adapter

Flywheel & Flywheel Housing

SAE standard rotation

Fuel System

Gas admission valves -- electronically controlled fuel supply pressure

Gas admission valves -- electronically controlled fuel supply pressure

Ignition System

A4 control system — senses individual cylinder detonation and controls individual cylinder timing

A4 control system — senses individual cylinder detonation and controls individual cylinder timing

Lube System

Crankcase breathers — top mounted

Oil cooler

Oil filter

Oil pan drain valve

Crankcase breathers — top mounted

Oil cooler

Oil filter

Oil pan drain valve

Mounting System

Engine mounting feet (six total)

Protection System

Electronic shutoff system with purge cycle

Crankcase explosion relief valves

Gas shutoff valve

Electronic shutoff system with purge cycle

Crankcase explosion relief valves

Gas shutoff valve

Starting System

Air starting system

Air starting system

General

Paint — Cat yellow

Vibration dampers

Air Inlet System

Heavy-duty air cleaner with precleaners and rain protection

Charging System

35 Amp & 65 Amp chargin alternators - CSA approved

35 Amp & 65 Amp chargin alternators - CSA approved

Exhaust System

Flexible bellows adapters

Exhaust expander

Weld flanges

Flexible bellows adapters

Exhaust expander

Weld flanges

Fuel System

Fuel filter

Gas pressure regulator

Flexible connection

Low energy fuel system

Corrosive gas fuel system

Instrumentation

Remote data monitoring and speed control

Compatible with Cat Electronic Technician (ET) and Data View

LCD display panel

Color HMI display

Modbus and Ethernet capable

Lube System

Air or electric motor-driven prelube

Duplex oil filter

RH service

Lube oil makeup system

Air or electric motor-driven prelube

Duplex oil filter

RH service

Lube oil makeup system

Mounting System

Mounting plates (set of six)

Power Take-Offs

Front stub shafts

Starting System

Air pressure reducing valve

Natural gas starting system

General

Engine barring device

Damper guard

30 Mins

30 Mins